Wafer Vision Inspection Handler:

Wi8i G2

Benefits

Robust Inspection Algorithm

- Dynamic Inspection Region Selection

- Flexible Dimension Measurement

- Configurable Defects Categorization

- Customizable E-Map Generation

- Raw & Mounted Wafer Loading

- SECS/GEM Ready

- Data Collection Charting

- Yield Optimization by Offline Verifier

- Color Inspection

Sophisticated Hardware Design

- Imaging by 25 Megapixels High-Resolution Camera

- Automated & Fast Conversion within 3 Magnification Lenses

- Raw Wafer Warpage Handling

- Bernoulli Dual Arm Raw Wafer Robot

- Intelligent Autofocus Technology

- Customized LED Lighting

- Bottom Vision Inspection

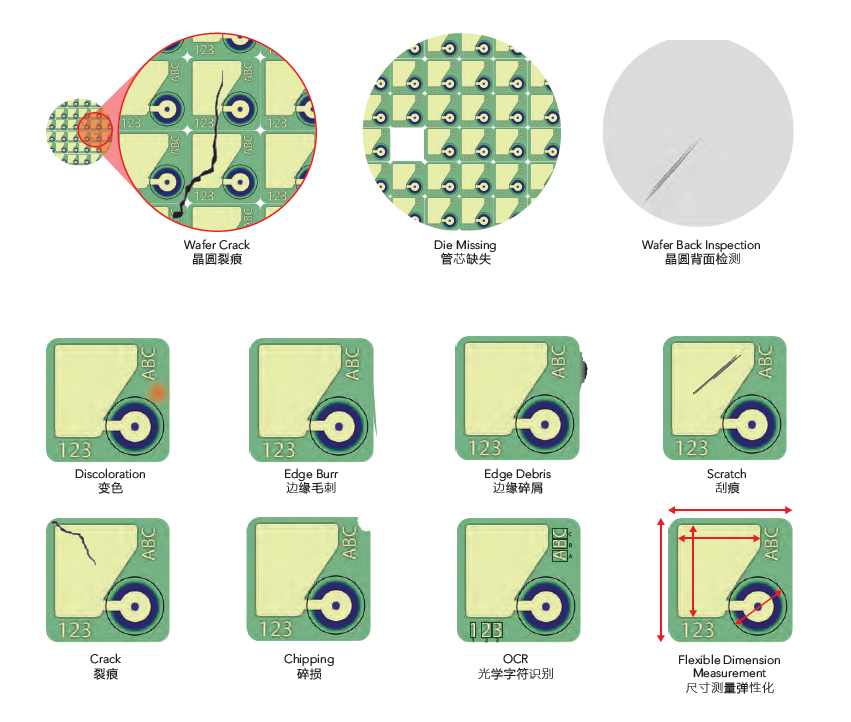

Inspection Criteria

Specification

| Model Type | Wi8i G2 | ||

| Wafer Input Type & Size |

Raw Wafer : 6*(150mm), 8*(200mm), 12*(300mm) Hoop Ring : 4*(100mm), 6*(150mm), 8*(200mm) – manual loading Framed Wafer: 6*(150mm), 8*(200mm), 12*(300mm) |

||

| Camera Lens | 2X | 5X | 7.5X |

| Accuracy | 2.2μm/ pixel | 0.9μm/ pixel | 0.6μm/ pixel |

| Field of view | 9.1mm x 9.1mm | 3.6mm x 3.6mm | 2.4mm x 2.4mm |

| System Capability |

Offline Verifier Wafer Automated Loader-Unloader |

||