Tray-to-Tray Series:

TH3000i

Benefits

2 X 14 Pick Up Nozzles

Maximize machine throughput up to UPH 60K (tray to tray)

Multi-Nozzles Sorting Mechanism

1 X 2 fully motorized pick-up arm for fast & reliable sorting

2 X 14 pick-up arm for end-lot full row sorting

Auto Nozzles Pitch Conversion

Programmable & Automated nozzles pitch conversion to minimize setup time

Double-Unit Detection

Dual row laser height measurement sensors to

detect double unit tray pocket

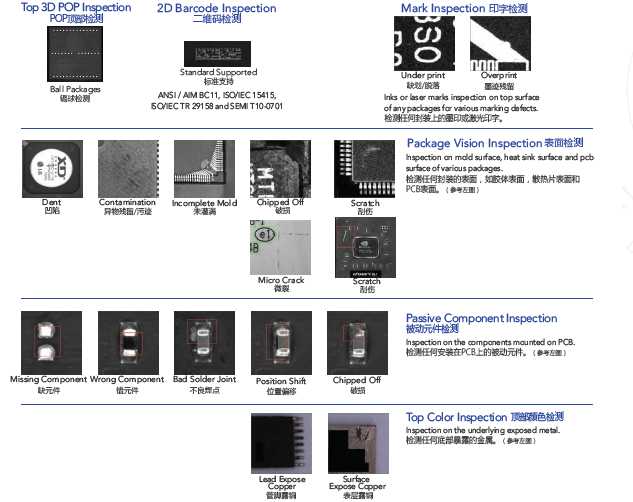

Inspection Criteria

Top Inspection

Bottom Inspection

Specification

| Model Type | TH3000i |

| Package Inspected | BGA, QFP, QFN, CSP, TSSOP, MSOP, SOP |

| Package Size | 2mmx2mm to 120mmx120mm |

| Handling Mechanism | Tray-to-Tray |

| UPH | Up to 60K (Tray-to-Tray) |

| Pick-up Heads | 1 x 14 (2 x 14 Optional) |

| Vision Inspection | 3D Vision Inspection, Leaded Packages Inspection, Ball Packages Inspection, Leadless Packages Inspection, Top 3D POP Inspection, 2D Barcode Inspection, Mark Inspection, Package Vision Inspection, Passive Component Inspection, 6S Color Inspection |

| Machine Dimensions | 1935mm(H) x 1740mm(W) x 2330mm(L) |