Post Seal Vision Handler:

VR20i G2

Benefits

Dual Tracks

Dual tracks design minimizes machine idle time

Auto Track & Dummy Reel Width Conversion

Auto Track and Auto Dummy Reel Width Conversion which cater tape width of 8, 12, 16, 24 and 32 mm by system triggering.

Enhanced Auto Labelling

Enhanced auto labelling module with more precise and higher label sticker capacity

Multiple Vision Systems

Multiple vision system perform Tape Seal Inspection, Mark Inspection, Package Inspection, Lead Inspection & Bottom Carrier Tape Inspection.

Auto Tape Insertion into Dummy Reel

Auto tape insertion into dummy reel feature reduces human handling and machine stoppages

AUX Vision Systems

Auxiliary Stations could be added to meet customer’s additional inspection requirement – 2.5D Lead Inspection, Colour Inspection, etc.

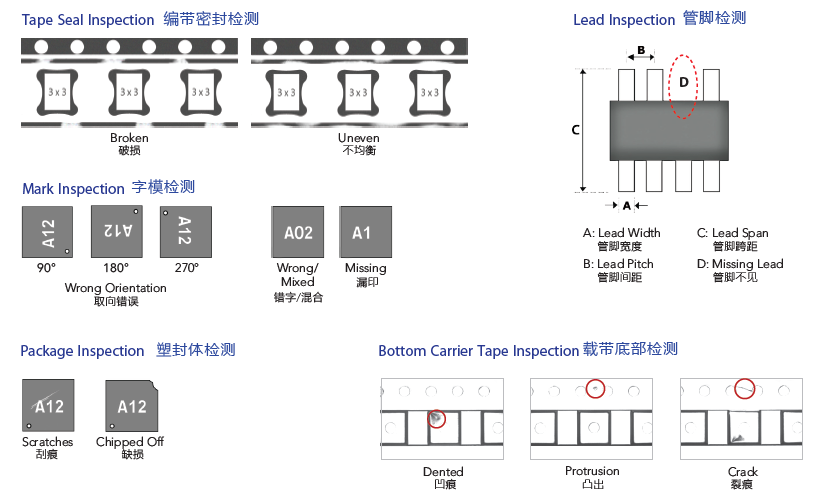

Inspection Criteria

Specification

| Model Type | VR20i G2 | ||||

| Carrier Tape Width | 8, 12, 16, 24, 32 mm | ||||

| UPH |

2mm pocket pitch (8mm carrier tape width) |

>130K |

12mm pocket pitch (16mm carrier tape width) |

>38K | |

|

4mm pocket pitch (8mm carrier tape width) |

>80K |

16mm pocket pitch (24 mm carrier tape width) |

>30K | ||

|

8mm pocket pitch (12mm carrier tape width) |

>60K |

24mm pocket pitch (32mm carrier tape width) |

>18K | ||

| Inspection Criteria |

Tape Seal : Broken / Open Seal Uneven Seal |

Mark: Wrong Orientation Wrong/Mixed Mark Missing Mark |

Package: Scratches Chipped Off Contamination |

Lead : Lead width Lead Pitch Lead Span Missing Lead |

Bottom Carrier Tape : Dented Potrusion Crack |

| Accuracy | +/- 15μm | N/A | N/A | +/- 15μm | N/A |

| Min. Detectable Defect Size | N/A | N/A | 150 μm x 150 μm (6mils x 6mils) | N/A | 300μm x 300μm (12mils x 12mils) |

| Reel Size | 178 mm (7″) to 330mm (13″) | ||||

| Package Type | SOT/SC, SOD, SOIC, QFN / MLP, LED | ||||

| MTBA | >60mins | ||||

| MTBF | >200hrs | ||||